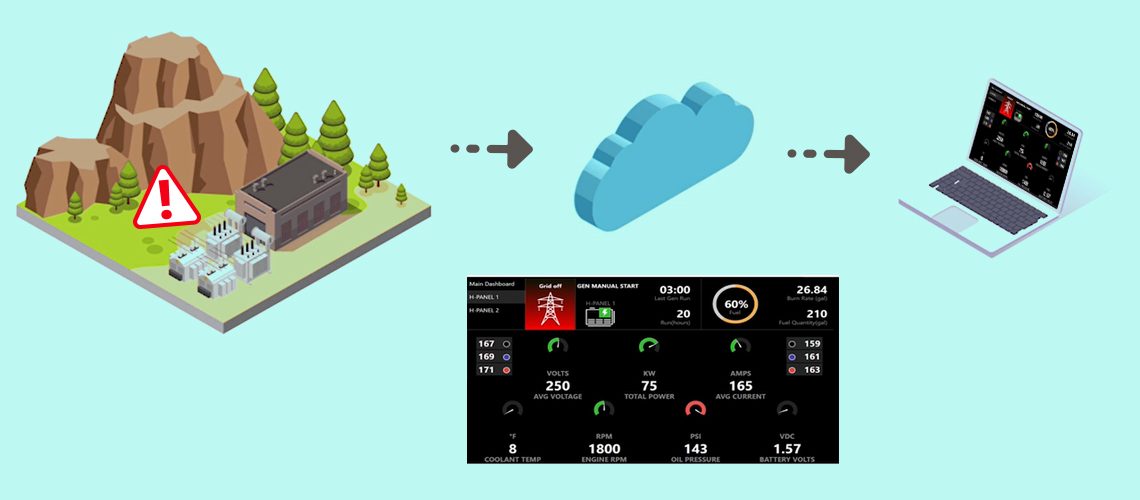

More Savings and Control with Remote Monitoring and Management

As of this writing in the tail end of 2020, businesses have a tough row to hoe. Remote Monitoring and Control (RMC) solution can provide the visibility and control of your facilities elements thus allowing businesses to optimize their operating expenses (OPEX). Make sure your business survives the coming years by trimming the operational inefficiencies now.

Case Study in Inefficiency Canada and other Northern tier regions are subjected to extreme weather. Generators at telecom sites rely on block heaters to keep them functioning optimally in this extreme climate. Block heater and generator set installations must be able to withstand fluctuating environmental conditions. This particular customer’s installations were at multiple locations, some of which were quite remote. A set run schedule was requiring block heaters in all locations to run for the same duration, at the same intervals, with fixed temperature settings. The current system could only be adjusted manually. Once AI based Remote Monitoring and Control solution was deployed, the scheduling could be easily optimized for each site.

Problem Identified

The problem faced by this specific customer was due to the non-optimal Generator block heaters run. Since the block heaters were running longer than they needed, creating high energy usage, and wasting a lot of power. This was costing the company money, both in energy cost, in the longevity of the block heaters, and in man-hours for scheduled site-specific maintenance.

Lingering Issues:

- High Energy Bills

- High Maintenance Cost

- High Carbon Footprint

Running the block heaters inefficiently resulted in over $1100 in energy consumption per site every year. If the company wanted to change up the schedule of the block heaters at individual sites, they had to send someone out there to do it. This resulted in regular site visits, costing the company additional funds in labor and transportation expenses. Any changes needed to coincide with the site visits. Special site visits to remote areas resulted in additional labor costs and a larger carbon footprint for the company.

Problem Solved

Upon deploying a comprehensive AI based Remote Monitoring & Control solution, the operational inefficiencies were identified. With RMC solution in place, two important things helped reduce the energy consumption

- Ongoing energy monitoring

- The ability to remotely monitoring and control the Generator Block Heater test/run schedules

Power usage was reduced, saving the customer over $500K per year in energy cost alone. The customer had 800 sites affected by the same inflexible run schedule. Implementing Remote Monitoring and Control solution gave the company much needed flexibility in regard to their block heater deployment. They were able to have more control over the energy usage costs at each site. Energy Monitoring Equipment generated data that helped the company visualize energy consumption site by site and reduce it in total by over 55%.

- $500K of savings per year in energy cost alone.

- Over 55% reduction in annual energy consumption

- Lower Carbon foot print

Once the RME (Remote Monitoring Equipment) was in place, changes could be made without requiring site specific trips by technicians. Labor costs were reduced, as well as the company’s carbon footprint. With this Generator Monitoring and Control system, it was possible to remotely manage the block heater run schedule and adjust it to suit fluctuating weather conditions. Bringing smart solutions to business problems is especially necessary as businesses face increasing competition. Every dollar saved through efficiency can be reinvested back into your business.

Innovation keeps businesses in the game. Contact us for more information on how to efficiently streamline your business.