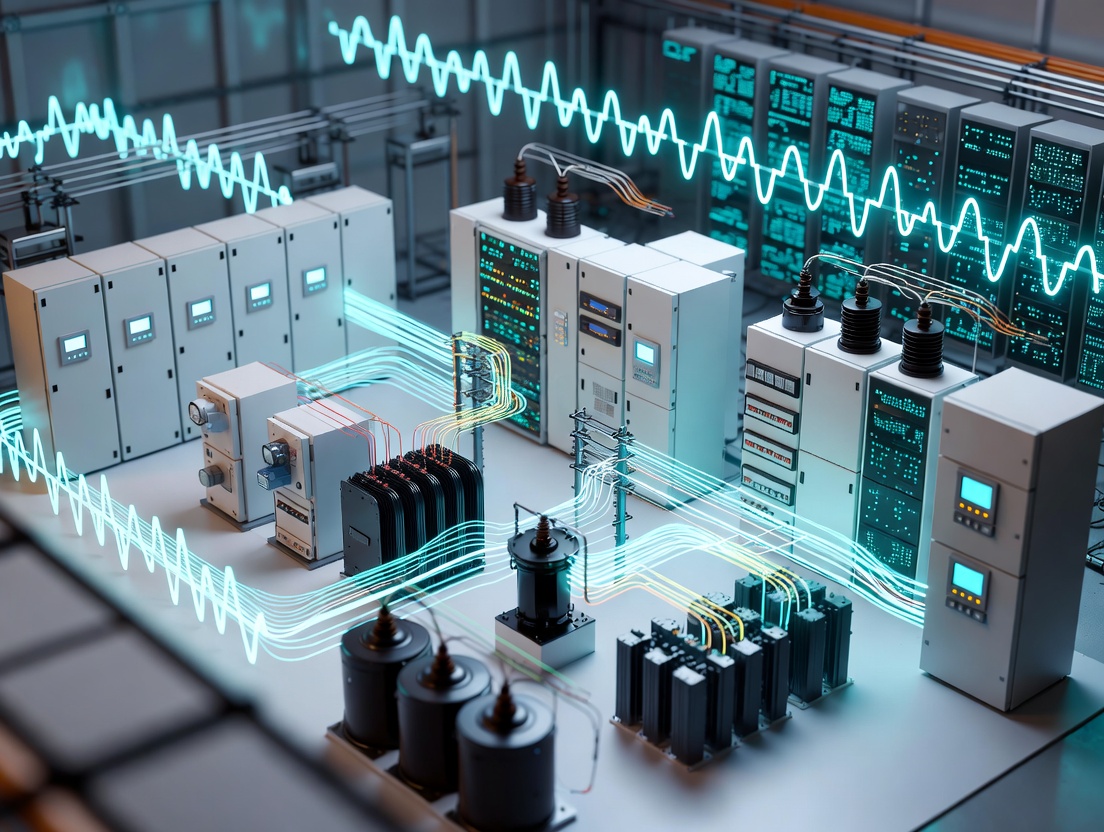

Increasing operational demands across modern facilities require precise control of energy usage and coordinated real-time demand management. Energy Demand Management supports stable power availability by aligning facility load behavior with system capacity, grid conditions, and infrastructure performance targets. This approach strengthens resilience for critical environments and supports both facility-level planning and grid-responsive load management. It also enables critical facility demand optimization and coordinated demand management for infrastructure across large, multi-site operations.

Demand charges represent 30-70% of your electricity bill, based on your single highest 15-minute power spike each month. One equipment surge costs you all month long.

AxIn platform prevents these peaks. AI forecasting predicts spikes before they happen. Automated controls adjust HVAC, shed non-critical loads, stagger equipment starts, and coordinate battery discharge—without impacting operations.

Typical results: 10% peak reduction = 3-7% lower total electricity costs. ROI in 12-24 months for facilities spending $20K+/month on demand charges.

Zero manual intervention required.

– HVAC systems – Setpoints, compressor staging

– Lighting – Non-critical areas during peaks

– IT equipment – Non-essential servers

– Battery systems – Strategic discharge timing

– Equipment staging – Prevent simultaneous starts

Integrates via Modbus, BACnet, or dry contacts.

– Facilities with hefty per month demand charges

– Operations with HVAC or battery systems

– Multi-site organizations needing standardized control

– Time-of-use tariff locations

Industries: Telecom towers, data centers, cable landing stations, manufacturing, cold storage

Load management solutions provide structured control over energy consumption patterns to maintain system stability during peak conditions. These solutions coordinate mechanical loads, HVAC systems, backup power assets, and digital infrastructure activity to maintain efficient facility operation. Automated scheduling and capacity-based execution allow facilities to limit stress on primary electrical distribution networks. Grid-responsive load management features can also be integrated to support grid flexibility programs and reduce operational risk during high-demand intervals.

Energy consumption optimization focuses on reducing non-essential loads while maintaining consistent operational performance levels. Data-driven analysis supports control strategies that manage equipment cycles, adjust performance levels, and minimize energy waste. This optimization approach is suitable for environments requiring critical facility demand optimization and supports long-term cost control. Demand management for infrastructure is strengthened through continuous monitoring and data-driven energy control adjustments across all active systems.

An integrated demand management system brings together data collection, load analysis, control actions, and performance reporting into a single unified platform. This system tracks energy usage trends, identifies load peaks, and activates predefined control strategies to prevent overload events. It also enhances the ability to participate in grid-responsive load programs initiatives by responding to grid signals and optimizing facility load accordingly. Centralized decision-making supports stable operations for high-capacity facilities and distributed networks.

Intelligent energy monitoring enables precise tracking of power quality, load distribution, and equipment-level consumption in real time. This capability strengthens critical facility demand optimization and brings greater transparency to energy-intensive operations. Monitoring data helps detect anomalous trends, allocate load efficiently, and maintain operational continuity. Combined with demand management for infrastructure, this monitoring layer ensures a more predictable and controlled energy environment.

Reliable energy management requires structured processes, advanced monitoring capabilities, and coordinated demand control strategies. Key strengths include:

PLC Group delivers energy demand management solutions that combine monitoring, control, optimization, and system integration to support reliable, balanced infrastructure performance. Critical facility demand optimization, grid-responsive load management, and integrated monitoring ensure long-term efficiency and operational reliability.

Connect with PLC Group today to implement fully integrated demand management strategies.

Fees based on your highest 15-minute power spike each month—typically 30-70% of your bill.

10% peak reduction = 3-7% lower total electricity costs. Typical ROI: 12-24 months for facilities spending $20K+/month.

No. AxIn only adjusts non-critical loads and keeps HVAC within ±2°F. Critical systems stay untouched.

HVAC, lighting, battery chargers, IT equipment, generators—anything with Modbus, BACnet, or dry contact interfaces.

12 months of utility bills (to identify peaks) and access to equipment controls. Implementation: 8-12 weeks.