OPEX Reduction

energy and maintenance costs reduced

Predictive Maintenance

based on trends and analysis

Theft Prevention

protection of assets and fueling

Budget Forecasting

for fuel and assets

Common Problems

In the increasingly competitive environment, MSO’s are continuously challenged to keep the network availability high while keeping operating costs low. Backup generators play a vital role in case of power outages to keep the services running. There are several points of failure while dealing with the Generators, such as Fuel levels, leakages, startup batteries, block heaters, etc. Generators require continuous testing to ensure availability in case of power outages due to natural disasters such as snowstorms, hurricanes, and others. This requires ongoing internal or third-party field resources. This task becomes even more challenging in extreme weather conditions. The current pandemic has made it even harder for adequate safety measures and planning to ensure physical contact and compliance with the health regulations.

The safety and security of the personnel coupled with the inefficiency pose a big issue for MSO’s. This is one of the many challenges that may be solved with the PLC AI-based Remote Monitoring and Control Solutions. A set run schedule requires extensive labour hours, vehicles, drive times, and expenses, taking the time away from other equally critical issues. These are the problems identified regarding the Generators’ reliable, safe, and cost-efficient operation for Mission Critical Operations. Genset Periodic and on-demand testing requiring field resources and expertise. Genset Fuel levels and leakage issues could only be physically detected. This could result in non-availability of the fuel when required, as well as environmental impacts. Not detecting Genset battery failures in time, resulting in not running when required. Block heaters year-round fuel consumption. Often times block heaters’ issues remain undetected until the Genset fails to start.

Key Features

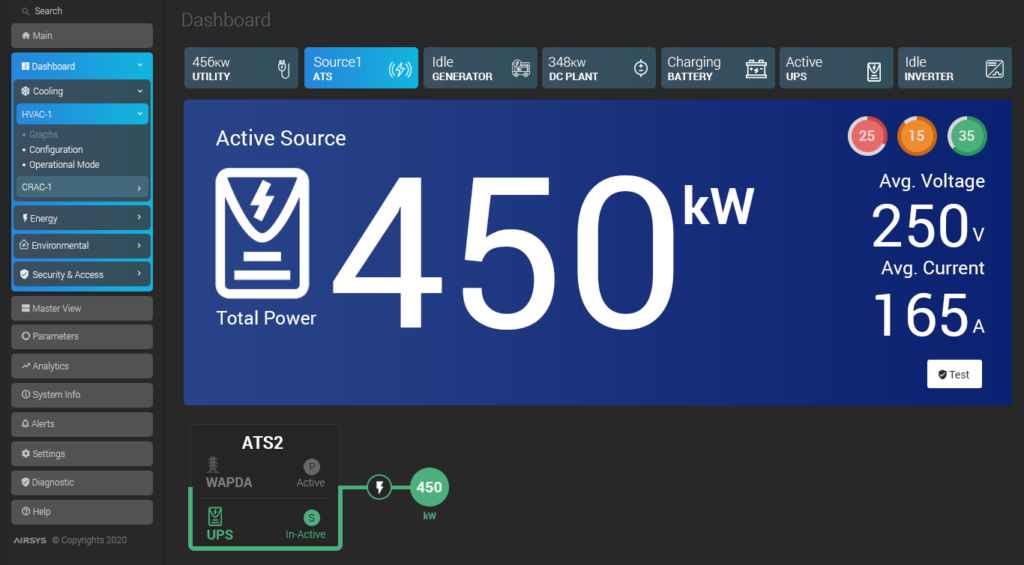

- ATS control

- Block heater control

- Block temperature

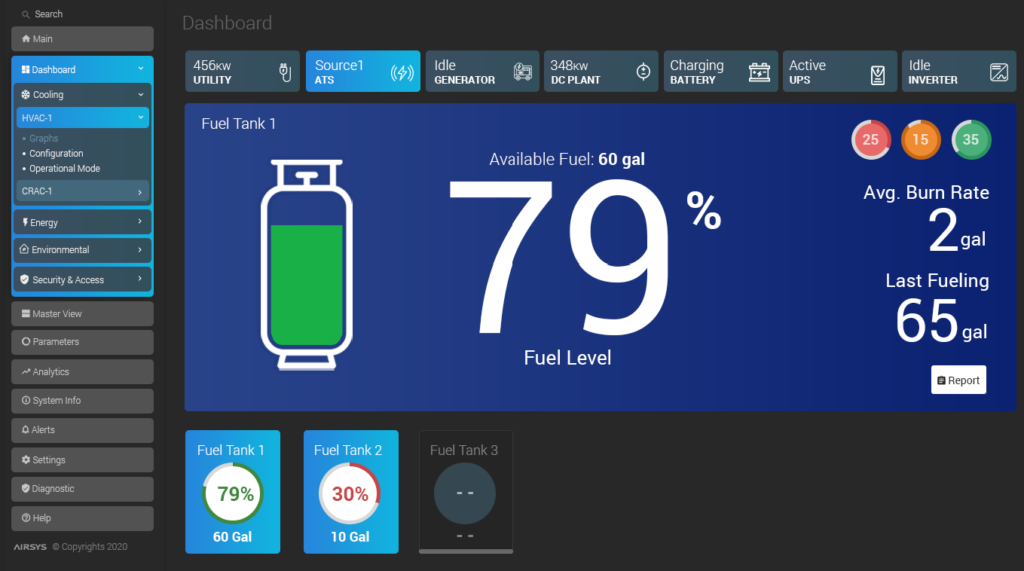

- Fuel monitoring and alerts

- Generator run hours

- Generator battery monitoring

- Generator failure alerts

- Maintenance alerts

- Mains power failure

- Remote exercise and remote ON/OFF

Reliable Backup Power

Backup generators are a critical part of the facilities infrastructure to ensure network availability. Depending on the geographical region, there are many issues associated with backup generators such as fuel theft, leakage, generator frequent exercise, failing batteries and inefficient block heaters.

PLC’s generator and fuel monitoring & control solution provides a comprehensive solution to manage these issues in real-time and eliminates the need for site visits or other expensive security measures. Our solution works with different types of gensets from various manufacturers.

Multi-Vendor Integration

Our Solution

PLC has made its mission to enable Telecom companies to safely and reliably maintain their facilities network using Remote Control and Monitoring. The added benefits are the OPEX reduction requiring less driving and travel times.

A comprehensive Remote Monitoring solution was deployed, enabling the safe remote testing of the Generators to monitor the following parameters and stats on the go:

- Real-time fuel monitoring.

- Real-time leakage detection.

- Real-time battery fault detection.

- Real-time block heater energy optimization and failure detection.

Common Problems

In the increasingly competitive environment, MSO’s are continuously challenged to keep the network availability high while keeping operating costs low.

Backup generators play a vital role in case of power outages to keep the services running. There are several points of failure while dealing with the Generators, such as Fuel levels, leakages, startup batteries, block heaters, etc.

Generators require continuous testing to ensure availability in case of power outages due to natural disasters such as snowstorms, hurricanes, and others. This requires ongoing internal or third-party field resources. This task becomes even more challenging in extreme weather conditions.

The current pandemic has made it even harder for adequate safety measures and planning to ensure physical contact and compliance with the health regulations. The safety and security of the personnel coupled with the inefficiency pose a big issue for MSO’s. This is one of the many challenges that may be solved with the PLC AI-based Remote Monitoring and Control Solutions.

This particular case involved multiple installations over a large geographical area, some of which were quite remote. A set run schedule was requiring extensive labour hours, vehicles, drive times, and expenses, taking the time away from other equally critical issues.

These are the problems identified regarding the Generators’ reliable, safe, and cost-efficient operation for Mission Critical Operations.

Genset Periodic and on-demand testing requiring field resources and expertise.

Genset Fuel levels and leakage issues could only be physically detected. This could result in non-availability of the fuel when required, as well as environmental impacts.

Not detecting Genset battery failures in time, resulting in not running when required.

Block heaters year-round fuel consumption.

Often times block heaters’ issues remain undetected until the Genset fails to start.

Feature Elaboration

- Generator Controller, Web Server, Protocol converter and Gateway.

- Full Remote Visibility and control for backup or Primary Gensets.

- Replace Multiple Controller from multi vendors with single unit.

- Non intelligent and Intelligent Generator support.

- Diesel, Propane and Natural Gas monitoring.

- Eliminate theft with Real time visibility.

- Integration with SNMP Gateways, SMS and email.

- Intelligent maintenance visits with Run hours measurements.

- Eliminate site visits with remote exercise with complete testing and reporting.

- Optimize Energy with efficient Block heater control.

- Detect Genset battery issues with remote testing.

- Schedulable remote testing and reporting reducing site visits.

- Predictive maintenance alerts.

- Generator output load

- Failure alerts.

- Energy optimization on block heaters.

- Consolidated alarms and incidents.

Why Us?

With many initiatives are competing for the CAPEX within the organizations, it is crucial to choose the initiatives that provide the highest Return on Investment (ROI).

Our solution was estimated to deliver the ROI of fewer than 18 months, resulting in ongoing OPEX savings, as well as the following intangible benefits:

- Network reliability improvement

- Improved customer client retention

- Carbon footprint reduction

- Safe and rapid response time in case of natural disasters

OEM Integrations

Learn More About Generator and Fuel Monitoring & Control Solutions

Eliminate Site Visits

Energy Optimization

Integration with SNMP

Schedulable Remote Testing

Multi-Vendor to Single Unit

Increased Visibility