PLC Group engineers universal controllers designed to consolidate facility automation, sophisticated energy management, and operational control into a single, unified connected ecosystem.

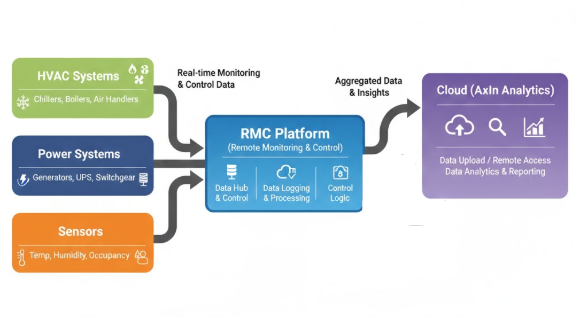

Our platform seamlessly integrates critical infrastructure—including HVAC systems, diverse power sources, environmental sensors, and security units—to deliver:

Built on standard industry communication protocols, a scalable architecture, and native support for advanced analytics (via AxIn Software), PLC Group controllers provide the ultimate precision and flexibility required by demanding industrial, telecom, and data center environments.

Modern facilities operate as complex ecosystems, integrating electrical, mechanical, and IT infrastructure. Without a central control layer, managing these systems leads to inefficiency, inconsistent performance, and increased downtime. Universal controllers create that control layer linking all assets into one intelligent network.

These controllers synchronize real-time data, optimize system behavior, and respond instantly to environmental changes or equipment status. This results in higher equipment reliability, better energy optimization, and improved asset lifespan. By enabling automation and data-driven decision-making, PLC Group’s controllers help organizations meet operational SLAs, energy efficiency goals, and sustainability standards.

Our HVAC and Industrial Automation Controllers are engineered to be the universal nexus for facility control. They seamlessly integrate both legacy and intelligent systems, enabling flexible deployment from single-site operations to expansive global networks, all while ensuring secure and interoperable control.

I. Universal Integration & InteroperabilityOur controllers are built for the heterogeneous environment of modern infrastructure, ensuring they can communicate with everything from basic sensors to complex SCADA systems.

II. Resilient Reliability & Adaptive PerformanceEngineered for continuous uptime, our controllers ensure stable performance by making smart, real-time decisions locally, protecting your assets from network instability.

III. Secure Management & ConnectivityWe provide secure, comprehensive tools that enable remote management and guarantee the integrity of your operational data and control access.

These combined capabilities empower operators to manage widely distributed assets with precision and confidence, achieving unparalleled stability and continuous uptime across all facility layers.

PLC Group’s industrial automation controllers and BMS controllers combine advanced control logic with integrated analytics to enhance efficiency, safety, and cost performance.

Key operational benefits include:

These benefits directly translate into improved operational resilience, measurable energy savings, and data-backed asset management.

PLC Group specialized controllers are engineered to supervise and integrate existing power systems, ensuring absolute continuity and reliable data communication across your critical infrastructure.

Intelligent Control for Resilient Power SystemsOur controllers and gateways are designed to interface directly with existing Generator and Automatic Transfer Switch (ATS) controllers. This integration allows PLC Group’s platform to achieve superior operational resilience by:

PLC Group Modbus Gateways function as the intelligent translation and communication layer, seamlessly linking legacy equipment with modern control and analytics systems.

They dissolve interoperability barriers, ensuring a standardized, reliable data flow between devices from diverse manufacturers—including dedicated HVAC controllers, smart meters, and proprietary power control platforms.

Distinct Capabilities:

Together, these controllers and gateways maintain operational stability and power reliability by acting as the intelligence hub that supervises and optimizes all existing site power components.

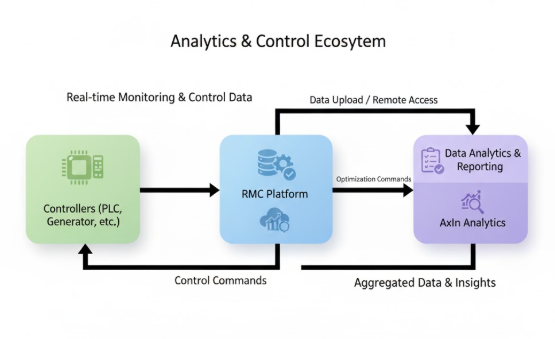

Every PLC Group controller connects to the RMC platform, forming an intelligent ecosystem for end-to-end visibility and control. The RMC platform consolidates environmental, electrical, and mechanical data into a unified dashboard, transforming raw inputs into actionable intelligence.

Integration Highlights:

This integration enables operators to manage geographically distributed facilities as if they were a single connected entity.

PLC Group provides integrated control solutions built on engineering precision and decades of field-proven expertise. Deployed in over 10,000 mission-critical environments—including global data centers, telecom networks, and major utilities—our solutions guarantee trusted, long-term performance and reliability under the most demanding conditions.

PLC Group’s universal controllers integrate automation, communication, and analytics into one platform. Their design ensures reliability, interoperability, and intelligence across every layer of infrastructure. Contact PLC Group to learn how these solutions can modernize your facility operations and enhance system performance.

They coordinate HVAC, power, and automation systems under one logic, reducing energy consumption and manual intervention.

Yes. They support industry-standard protocols like Modbus, SNMP, and BACnet for smooth interoperability.

They automatically manage genset operation, synchronize loads, and alert operators to faults in real time.

Yes. All communication is encrypted using TLS, and access is managed through role-based authentication.

Yes. The RMC platform enables remote configuration, diagnostics, and firmware updates for all connected controllers.

They regulate lighting, cooling, and environmental systems to maintain a balance between efficiency and comfort.