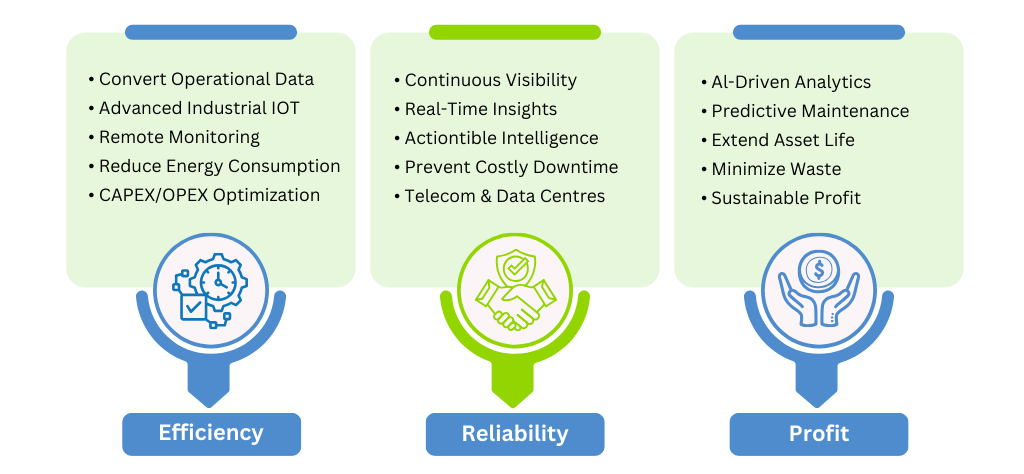

PLC Group helps organizations convert operational data into measurable financial value. Through advanced Industrial IoT and remote monitoring solutions, we enable businesses to unlock efficiencies, reduce energy consumption, and achieve long-term CAPEX and OPEX optimization. By transforming real-time insights into actionable intelligence, we help decision-makers enhance performance, prevent costly downtime, and improve overall return on investment.

Our intelligent remote monitoring platforms deliver continuous visibility into assets and environments, ensuring reliability and precision across telecom networks, utilities, and data centres. With AI-driven analytics and predictive maintenance capabilities, PLC Group empowers teams to extend asset life, minimize waste, and build more resilient, cost-efficient operations, turning everyday data into sustainable profit.

Fault Surveillance

Site Management

Analytics and BI

Alarms Management

Tenant Management

Operational Excellence

Energy Efficiency

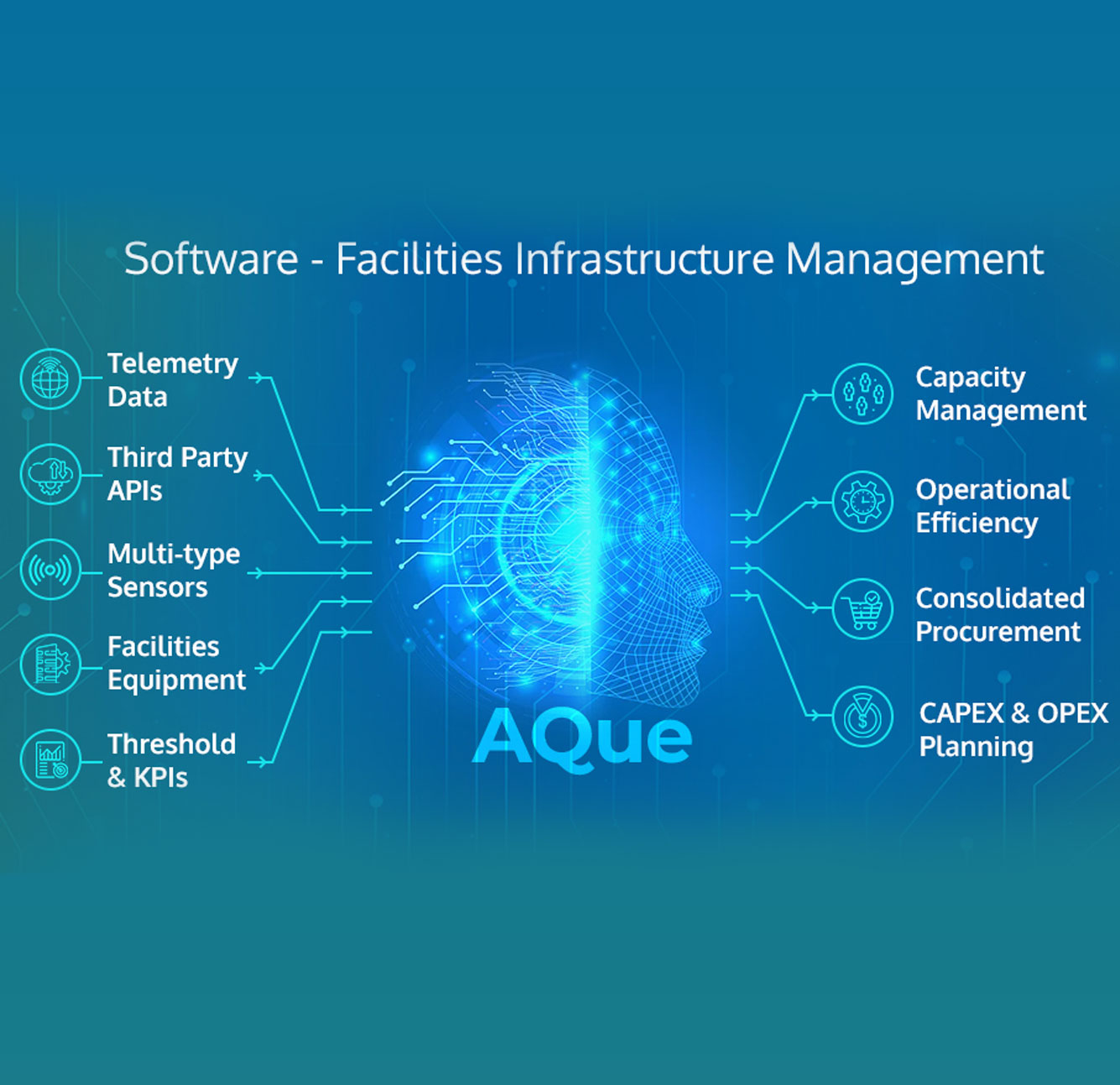

PLC Group’s Industrial IoT & Remote Monitoring Solutions combine intelligent hardware, advanced analytics, and automation within a unified platform. Each feature is engineered to deliver real-time visibility, predictive insights, and precise control across mission-critical operations.

An Industrial IoT platform powered by Artificial Intelligence and Machine Learning for predictive maintenance, smart operations, and optimized energy consumption.

An integrated remote monitoring system combining hardware and software for energy, environmental, and access management across multiple facilities.

Energy-efficient cooling systems engineered for telecom and data centres, ensuring stable operations and reduced energy overhead.

PLC Group offers flexible as-a-Service models that combine hardware, software, and analytics under a unified subscription framework. Each model—spanning Actionable Intelligence, RMS, Software, and Cooling—delivers scalability, simplified management, and predictable operational costs for critical facilities.

In facilities total cost of ownership

In planning and forecasting using AI

Across the facilities network

Based on historical data

No upfront fee for equipment and software

Includes hardware, software, maintenance and more

consistent OPEX reductions on energy and labour costs

Using artificial intelligence and machine learning

Using existing data and AI to drive results

Consistent OPEX reductions

No upfront costs required

We get paid on real results

receive instant CAPEX for cooling infrastructure

meet carbon emissions targets

pay only for the IT load cooling consumption

flexible financial management of your assets

Delivering complete, ready-to-use solutions from concept to deployment.

Providing innovative engineering expertise to solve complex challenges.

Ensuring smooth operations with proactive management and strategic support.

We deliver end-to-end solutions designed to meet your business goals.

From implementation to ongoing management, our expertise ensures efficiency and reliability.

PLC Group’s Industrial IoT & Remote Monitoring Solutions are deployed across diverse sectors where reliability and real-time intelligence are critical. From telecommunications and data centres to utilities, public safety networks, cable landing stations, and large-scale facilities management, each industry benefits from unified monitoring, energy optimization, and predictive analytics that ensure uninterrupted operations and measurable efficiency gains.

Enabling uninterrupted network performance through intelligent tower and shelter monitoring.

Delivering energy-efficient monitoring and control for power, cooling, and uptime optimization.

Ensuring real-time monitoring and control of coastal communication infrastructure.

Reliable energy performance depends on precise monitoring, accurate data, and intelligent control.

Supporting continuous reliability and readiness for mission-critical communication facilities.

PLC Group’s products and solutions follow a streamlined, results-driven process designed to ensure reliability and measurable improvement at every stage. From strategic collaboration to technology-led transformation, each phase is focused on maximizing uptime, efficiency, and operational intelligence across critical facilities.

We begin by fostering alignment across stakeholders — internal teams, partners, and customers — to build a shared understanding of goals, challenges, and opportunities. This stage ensures clarity, teamwork, and the foundation for impactful action.

Innovation drives everything we do. Leveraging advanced technology, data insights, and cross-industry expertise, we create smart, scalable technology-led solutions that redefine performance and efficiency. In this process, we turn insights into intelligent outcomes.

Finally, we transition from concept to reality, seamlessly integrating the innovative solutions into your core operations. This is where we scale the proven prototypes into enterprise-wide capabilities, delivering sustainable operational excellence, optimized costs, and measurable, long-term value that redefines your business landscape.

A remote monitoring system from PLC Group collects real-time data and control events to enable visibility and proactive intervention; it is needed whenever assets are dispersed, access is difficult, or uptime is critical.

PLC Group’s industrial IoT software supports integration via open protocols (Modbus, BACnet, SNMP, MQTT), allowing third-party equipment and PLCs to connect.

PLC Group’s offering includes dashboards, analytics engine, data storage, alerting modules, and control-logic software as part of the full system.

Industrial IoT platforms from PLC Group offer cloud-based, scalable device connectivity, analytics, and remote access beyond traditional SCADA, enabling broader remote monitoring solutions.

Yes — PLC Group’s facility monitoring system provides real-time energy-use data, trend analysis, and automated alerts to reduce energy consumption and operational costs.

The industrial IoT system features redundant connectivity, local data buffering, rugged hardware, and 24/7 support from PLC Group to minimize downtime.

Absolutely — PLC Group’s remote monitoring solutions are configurable to custom sensors, control logic, and industry-specific requirements without forcing generic setups.