MSOs must keep networks running during outages, but generators often fail due to fuel issues, leaks, weak batteries, and block heater faults. Manual testing and site visits are costly, risky, and difficult—especially in extreme weather or strict safety conditions.

These challenges lead to higher operating costs, safety risks, and unexpected generator downtime.

PLC Group’s Platform helps eliminate these issues with real-time visibility and automation.

energy and maintenance costs reduced

based on trends and analysis

protection of assets and fueling

for fuel and assets

Backup generators are a critical part of the facilities infrastructure to ensure network availability. Depending on the geographical region, there are many issues associated with backup generators such as fuel theft, leakage, generator frequent exercise, failing batteries and inefficient block heaters.

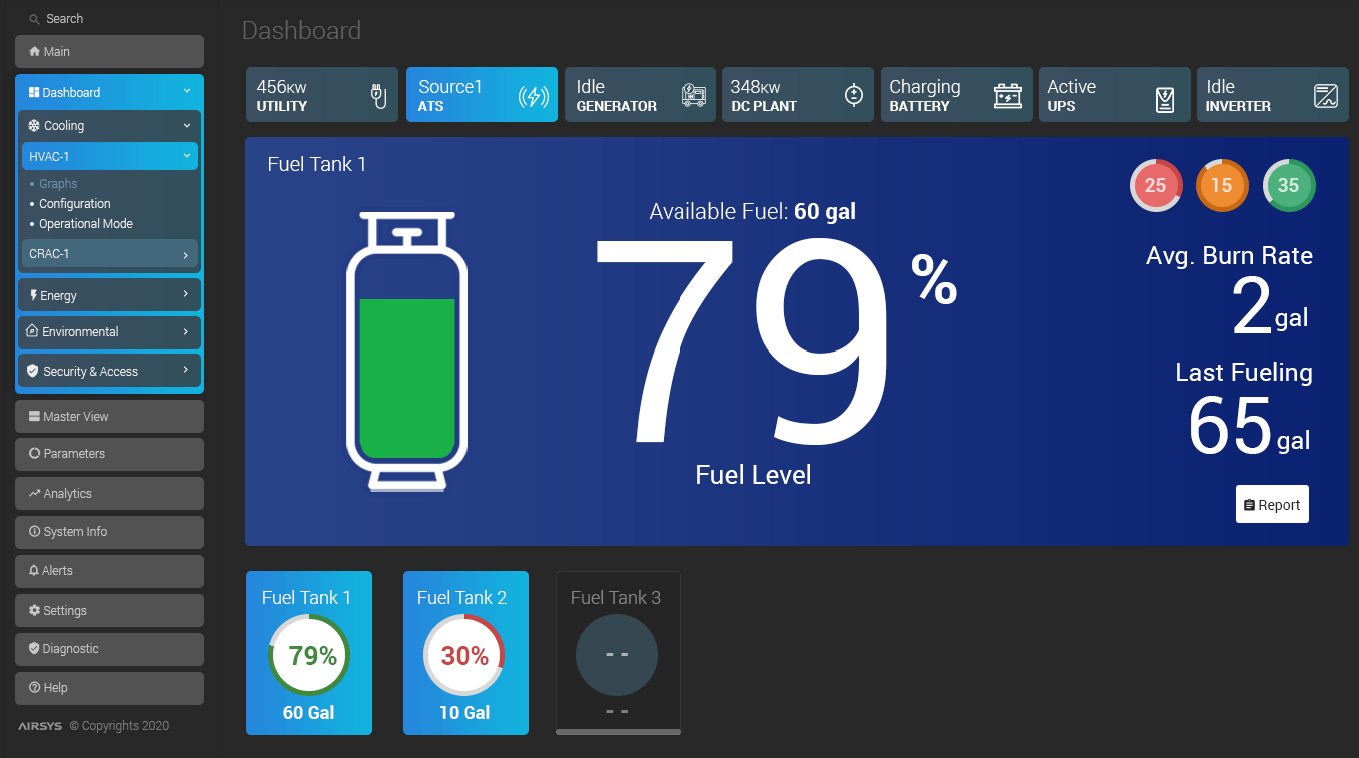

PLC’s generator and fuel monitoring & control solution provides a comprehensive solution to manage these issues in real-time and eliminates the need for site visits or other expensive security measures. Our solution works with different types of gensets from various manufacturers.

Our generator and fuel monitoring & control solution supports both intelligent and non-intelligent (legacy) generators including Generac, Kohler, Caterpillar, Cummins, John Deer, Deep Sea, etc. This solution helps in capacity planning based on generator load and to remotely test the generators and schedule maintenance alerts.

PLC has made its mission to enable Telecom companies to safely and reliably maintain their facilities network using Remote Control and Monitoring. The added benefits are the OPEX reduction requiring less driving and travel times.

A comprehensive Remote Monitoring solution was deployed, enabling the safe remote testing of the Generators to monitor the following parameters and stats on the go:

All of these steps resulted in huge OPEX reduction and improvement in reliability of the Genset assets. A comprehensive report was issued from the deployed hardware and software that could provide insights into the maintenance of the assets.

With many initiatives are competing for the CAPEX within the organizations, it is crucial to choose the initiatives that provide the highest Return on Investment (ROI).

Our solution was estimated to deliver the ROI of fewer than 18 months, resulting in ongoing OPEX savings, as well as the following intangible benefits:

Eliminate Site Visits

Schedulable Remote Testing

Energy Optimization

Multi-Vendor to Single Unit

Integration with SNMP

Increased Visibility