Modern critical infrastructure requires physical devices that can sense, control, and communicate with precision. PLC Group provides a complete hardware ecosystem designed to monitor, automate, and secure operational environments across telecom towers, data centers, edge sites, utilities, and cable landing stations.

Our hardware products form the foundation of reliable remote monitoring and control. Gateways, controllers, sensors, and energy meters work together to provide continuous visibility, environmental stability, energy optimization, and fast response across mission-critical operations. These systems support applications for HVAC Monitoring Systems, Remote Monitoring Tools, and HVAC Remote Monitoring, while keeping the focus on hardware-driven capabilities.

Remote visibility only works when the underlying hardware is designed for accuracy, durability, and interoperability. PLC Group’s portfolio enables:

This hardware-first approach helps operators maintain optimized and reliable facilities even in remote or unmanned environments.

PLC Group gateways serve as the primary communication bridge between field equipment and the RMC platform. They gather telemetry, execute commands, and ensure secure site-to-cloud communication.

A compact and rugged edge gateway engineered for distributed sites and micro-installations.

Key capabilities include:

A high-performance gateway designed for extensive or multi-equipment facilities.

Key capabilities include:

Both gateways provide the hardware backbone required for stable, secure remote monitoring applications.

PLC Group controllers manage equipment behavior, automate cooling sequences, regulate environmental stability, and deliver precise command control for critical infrastructure.

A compact controller built for smaller environments and smaller HVAC units.

An advanced controller for telecom, edge, and small data environments.

A universal controller designed for high-density operations.

These controllers form the control layer for cooling optimization, energy management, and site operations.

Sensors provide the real-time data required for accurate monitoring and automation. PLC Group sensors are engineered for reliability in demanding environments.

These sensors provide the data foundation for HVAC Monitoring Systems and Remote Monitoring Tools.

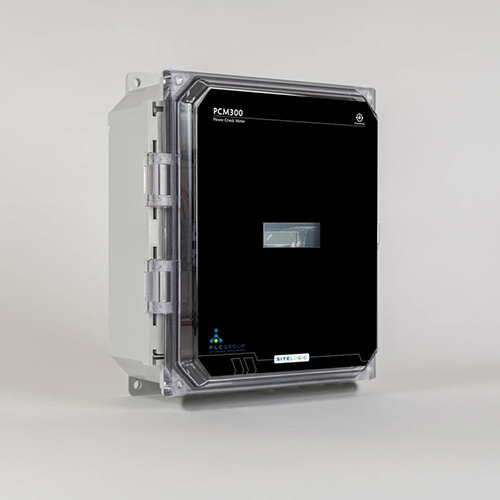

Energy meters help organizations scale their monitoring environment while improving power intelligence and equipment oversight.

PCM 300 Energy Meter: A multi-parameter energy meter that records power usage, voltage, current, power factor, and harmonics. It supports energy optimization initiatives and operational planning.

All hardware components interact via standardized industrial communication protocols. This allows the system to provide:

Together, this creates a hardware-driven monitoring framework that supports HVAC Remote Monitoring, energy optimization, and facility automation.

PLC Group hardware is actively deployed across:

Any environment that requires uptime, safety, and efficient operation benefits from robust hardware monitoring and control.

Choosing the right hardware partner is essential to maintaining reliable operations across distributed, mission-critical environments. PLC Group provides a hardware ecosystem that is engineered for durability, interoperability, and long-term performance. Every device is designed to meet real-world site demands while supporting modern automation and monitoring requirements.

Reasons to Choose PLC Group include:

PLC Group delivers hardware that enables real-time visibility, precise control, and operational confidence across complex and remote facilities.

PLC Group delivers a complete hardware foundation for mission-critical monitoring and control. Connect with our technical team to explore gateways, controllers, sensors, and energy meters for your remote and distributed sites.

Most installations use gateways, controllers, sensors, and energy meters to collect, process, and transmit operational data.

Yes, gateways such as Maple Edge-II and Maple Edge-III support multiple protocols and can connect to both modern and legacy devices.

Yes, controllers, including the TCU-MiniT+ and TCU-800 Micro, are built to interface with a wide range of HVAC systems.

It supports high input and output capacity, flexible configuration, and multi-system integration for complex sites.

Yes, several sensors, including fuel level sensors, PLC-ATHS, and PLC-PS-DAF, operate on Modbus or analog output formats.

It delivers immediate notification when grid power returns, helping operators reduce generator use and restart equipment quickly.

It measures power consumption, voltage, current, frequency, harmonics, and overall energy performance.

Yes. Accurate sensing and controller logic help detect temperature rises, airflow issues, power irregularities, and equipment faults before failure.

Yes. All hardware integrates with the RMC platform and can also work with third-party systems through open communication protocols.