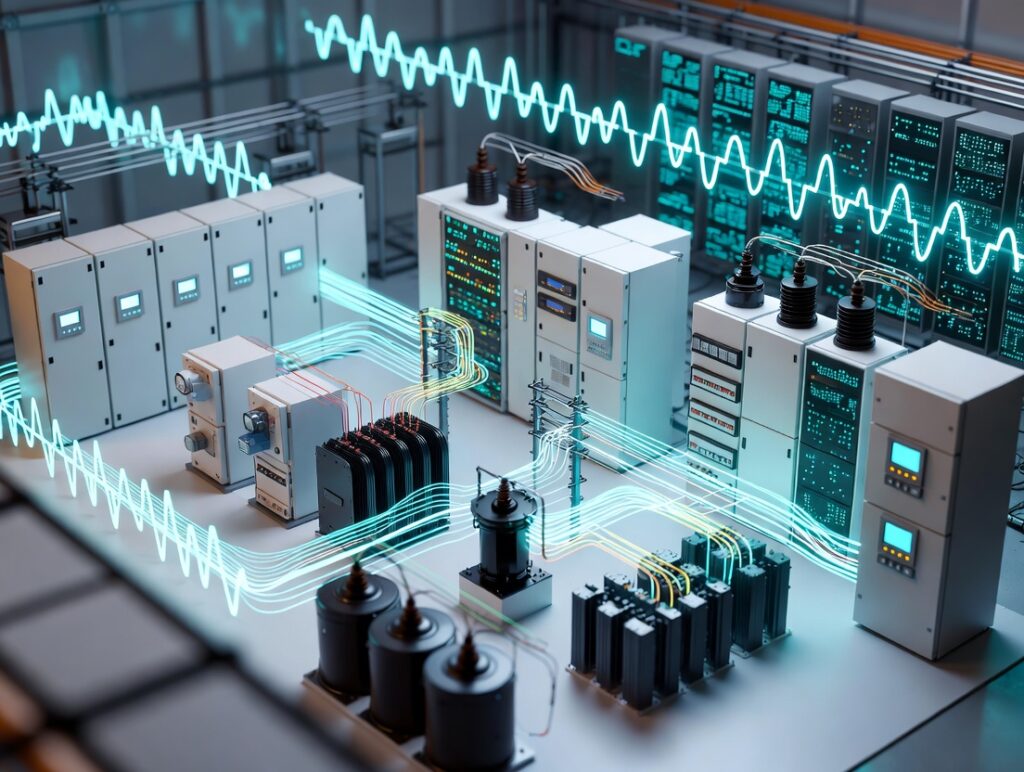

Industrial energy systems are becoming more complex due to distributed generation, variable loads, and bidirectional power flows. Power demand is no longer static. Facilities now require real-time insight, automated controls , and responsive grid interaction. This shift has made smart energy meters a core data source within modern industrial remote monitoring architectures. When integrated with advanced analytics and industrial IoT platforms, energy data becomes a driver of operational efficiency, cost optimization, and strategic decision-making.

For organizations managing critical infrastructure, energy visibility is no longer optional. It directly influences uptime, grid interaction, and long-term asset planning.

What Does Grid Flexibility Mean in Modern Energy Systems?

Grid flexibility refers to the ability of energy systems to adjust supply and demand in real time. Traditional grids were designed for unidirectional power flow. Modern grids are dynamic, distributed, and data-driven.

A Smart energy meter enables this flexibility by capturing granular power data at the asset, site, and network level. This data allows operators to respond instantly to changing load conditions.

Grid flexibility supports:

- Faster response to demand spikes

- Better integration of renewable energy

- Reduced strain on generation assets

- Energy and Demand Management for cost optimization

An intelligent Energy Monitoring System transforms raw electrical measurements into actionable insight. This capability allows facilities to align consumption with grid conditions proactively rather than reacting after issues occur.

What Are the Limitations of Traditional Electricity Meters?

Legacy electricity meters were designed for basic consumption tracking. They lackintelligence required for modern operations.

Key limitations include:

- No real-time visibility into energy usage

- Inability to detect power quality issues

- Manual data collection and delayed reporting

- No integration with automation platforms

These limitations create blind spots across industrial facilities. Without timely data, operators cannot prevent overloads, identify inefficiencies, or support grid-level coordination. Traditional meters also fail to support predictive maintenance or remote diagnostics.

How Do Smart Meters Enable Real-Time Demand Response?

A smart energy meter acts as a live data source within an IoT Energy Monitoring System. It continuously measures voltage, current, frequency, power factor, and harmonics. This information is transmitted securely to centralized monitoring platforms.

Real-time demand response becomes possible because:

- Energy data is available instantly

- Threshold-based alerts trigger automated actions

- Loads can be adjusted dynamically based on grid signals

An integrated Energy Monitoring System allows facilities to participate in demand response programs without manual intervention. Equipment loads can be reduced, shifted, or optimized during peak periods. This approach protects infrastructure while controlling operational costs and supports grid stability.

How Does Smart Metering Improve Grid Stability and Peak Load Management?

Peak demand places significant stress on electrical grids. Industrial facilities often contribute to these spikes due to high-capacity equipment and cooling systems.

Smart metering improves grid stability by providing:

- Continuous monitoring of load behavior

- Early detection of abnormal consumption patterns

- Data-driven load balancing strategies

When paired with advanced energy monitoring solutions, smart meters support automated peak shaving. Systems can reduce non-critical loads during peak windows. This reduces the risk of outages and supports grid-wide reliability and efficiency. Smart metering data improves planning accuracy and reduces emergency interventions and operational risk.

What Are the Long-Term Benefits for Utilities and Consumers?

Smart metering delivers measurable value over time. Both utilities and industrial consumers gain operational and financial advantages.

Long-term benefits include:

- Lower energy costs through optimized energy consumption

- Improved asset life from stable operating conditions

- Enhanced compliance and audit readiness

- Reduced downtime through predictive maintenance insights

For utilities, smart meters improve demand forecasting and infrastructure planning. For consumers they support better control over energy spend and operational performance. An IoT-enabled Energy Monitoring System turns energy data into a long-term strategic asset rather than a monthly report.

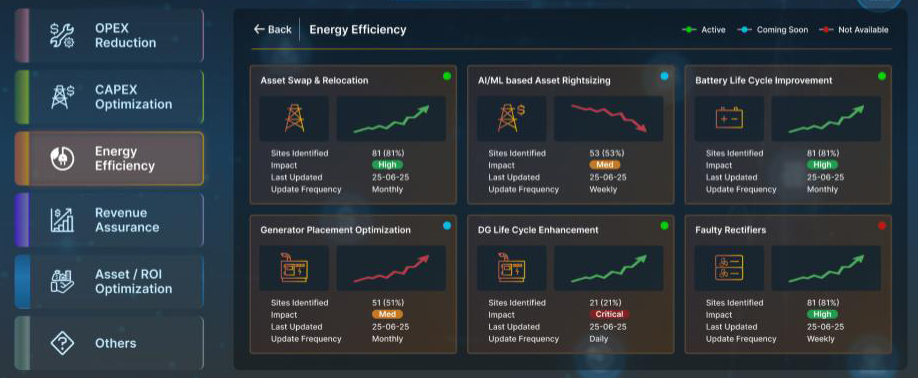

How Does Industrial Remote Monitoring Strengthen Energy Intelligence?

Industrial remote monitoring integrates smart meters with analytics platforms, automated control systems, and supervisory software to provide centralized operational oversight. This integration enables continuous operational optimization across distributed sites.

PLC Group delivers industrial IoT and remote monitoring solutions designed for critical infrastructure. Its platforms convert operational data into measurable financial value through predictive analytics and automation. Energy data from smart meters feeds directly into these systems, enabling real-time energy visibility and predictive insights.

This approach supports:

- Proactive decision-making

- Reduced operational risk

- Predictable performance outcomes

How Can Organizations Move Forward With Smarter Energy Monitoring?

Modern energy systems demand precision, speed, and integration. A smart energy meter is no longer a standalone device. It is a foundational component of intelligent energy infrastructure management.

By adopting integrated Energy Monitoring Solutions, organizations can align energy usage with grid conditions, protect critical assets, and improve long-term operational performance.

Contact PLC Group to learn how smart energy monitoring and industrial remote monitoring solutions can strengthen grid interaction, reduce risk, and unlock measurable business value.