Industrial remote monitoring refers to the use of connected hardware and software to track, analyze, and control critical assets from a centralized location. These systems collect real-time data from equipment, sensors, and infrastructure sites. The data is transmitted to centralized platforms to support monitoring, alerting, and analysis..

Modern industrial remote monitoring devices connect both intelligent (communicating) over standard industrial protocols and legacy (non-communicating) assets through various sensory elements to acquire telemetry data. They support operational continuity across geographically distributed facilities by enabling centralized monitoring and fault detection . This approach reduces reliance on manual site inspections by providing continuous system monitoring.

. For industries managing critical infrastructure, remote monitoring is no longer optional. It plays a pivotal role in ensuing network uptime, cost reduction , and asset protection.

Why Do Industrial Operations Rely on Remote Monitoring?

Operations teams manage complex environments with limited tolerance for failure. Real-time Remote monitoring and control reduces operational risk by providing continuous visibility into site performance.The timely identification of issues based on predictive analytics allow field personnel to take data-driven proactive actions instead of reactive response resulting in improved network uptime and availability. Industrial remote monitoring devices also help standardize operations across multiple locations. This consistency is essential for regulated and mission-critical environments.

How Do Industrial Remote Monitoring Devices Work?

Industrial Remote Monitoring devices are comprised of various sensory elements and aggregators for data acquisition on the site level. The main aggregator acquires telemetry data from various intelligent (communicating) assets through seamless integration via standard industrial protocols and from legacy (non-communicating) assets through various sensory elements. The telemetry data is further transmitted to the cloud/on-prem based centralized monitoring and management platform. The data is processed, analyzed and visualized for continuous remote monitoring, fault surveillance, reporting and analytics. This allows the relevant stakeholders to get a consolidated visibility and control of geographically dispersed assets on a unified platform.

This closed-loop model enables remote monitoring and controlled response actions without continuous on-site presence.

What Business Problems Do These Systems Solve?

Remote monitoring addresses several operational challenges that affect cost and reliability:

- Unplanned Downtime caused by undetected equipment failures

- Rising Energy Costs due to inefficient system operation

- Limited Visibility across distributed or unmanned sites

- Shortened Asset Life from delayed maintenance actions

Where Are Remote Monitoring Tools Most Commonly Used?

Remote monitoring is essential in industries where uptime and resilience are critical. These environments often operate 24/7 with limited on-site staff.

Common use cases include:

- Telecommunications networks and remote tower sites

- Data centers and edge facilities

- Cable landing stations and network hubs

- Utilities and renewable energy installations

- Public safety and emergency communication networks

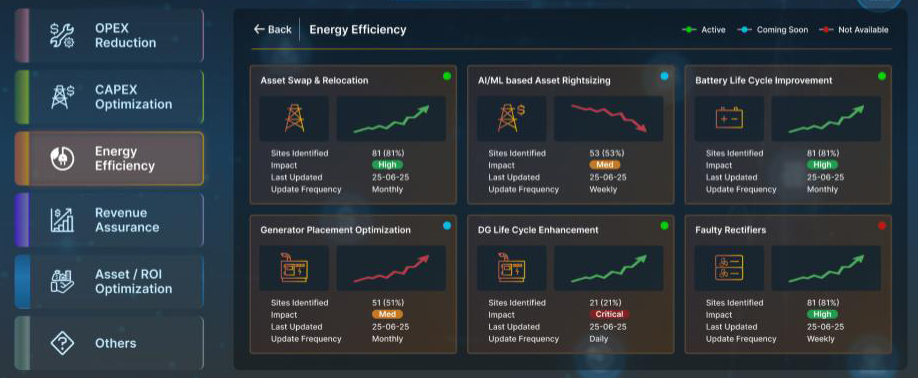

How Does a PLC Monitoring System Improve Decision-Making?

PLC Monitoring Systems allows comprehensive monitoring and control by unifying passive power, environmental, and security telemetry into a single pane of glass. By bridging the gap between legacy hardware and intelligent assets, the platform evolves beyond simple surveillance into an active orchestration engine that utilizes policy-based automation and predictive analytics. This centralized intelligence not only identifies root causes for non-performing sites but also optimizes power consumption and asset health, ultimately transforming raw operational data into strategic, data-driven decisions that maximize network uptime and business efficiency.

What Capabilities Should Industrial Monitoring Solutions Include?

Effective industrial monitoring platforms share several core capabilities:

- Real-Time Visibility across assets and environments

- Secure Data Transmission from edge to platform

- Scalable Architecture for growing site portfolios

- Predictive Maintenance Support through trend analysis

How Does PLC Group Support Industrial Remote Monitoring?

PLC Group provides industrial IoT and remote monitoring solutions for critical infrastructure management across North America. Established in 2014, the company focuses on converting operational data into measurable financial outcomes.

Its integrated hardware and software solutions connect assets to advanced analytics platforms. Analytical models are applied to historical and real-time data to support predictive maintenance and energy optimization.. Flexible as-a-Service delivery models enable scalability and predictable costs.

Through these capabilities, PLC Group helps organizations extend asset life, prevent downtime, and improve facility performance.

Why Does Industrial Remote Monitoring Matter for Long-Term Performance?

Industrial operations face increasing pressure to reduce costs while maintaining reliability. Remote monitoring enables proactive management instead of reactive fixes. It transforms operational data into a strategic asset.

By deploying industrial remote monitoring devices, organizations gain control, resilience, and efficiency. These benefits compound over time, supporting a stronger return on investment and operational stability.

Contact PLC Group to learn how industrial remote monitoring solutions can improve visibility, reliability, and performance across critical infrastructure.