Problem:

Wireless telecom operators in North America face various challenges within their offgrid sites. Usually these problems stem from little to no visibility at these sites due to non comprehensive remote monitoring and control solutions, locality and various environmental conditions.

Firstly, operators are unable to gain complete visibility of their site, as they do not have sufficient and actionable data regarding their equipment, such as generator status, run time, fuel level, battery and backup power status, temperature of overall site, and importantly, renewable energy (solar panels, wind turbines) production trends and its optimization.

Due to these blindspots, operators are unable to optimize their OPEX, as well as their total cost of ownership. Due to little to no visibility, generators at these offgrid sites may have a continuous runtime due to fault, which can increase carbon emissions and create a negative impact on the environment. This can also lead to the outage as the fuel consumption is higher than expected. Moreover, this also increases the energy inefficiency at these offgrid sites due to the operating cost of delivering fuel and consistent maintenance visits to repair the generators on site.

Lastly, as discussed, due to consistent maintenance visits by technicians, operators have to dedicate a large chunk of the overall budget to expensive maintenance costs for each of these offgrid sites.

Operators require a smart remote monitoring and control system that provides them complete visibility of their offgrid sites, which allows them to use real-time data analytics to make real-time decisions, ultimately reducing their generator runtime and the negative impact on the environment, making their sites more energy efficient and reducing maintenance costs.

Solution:

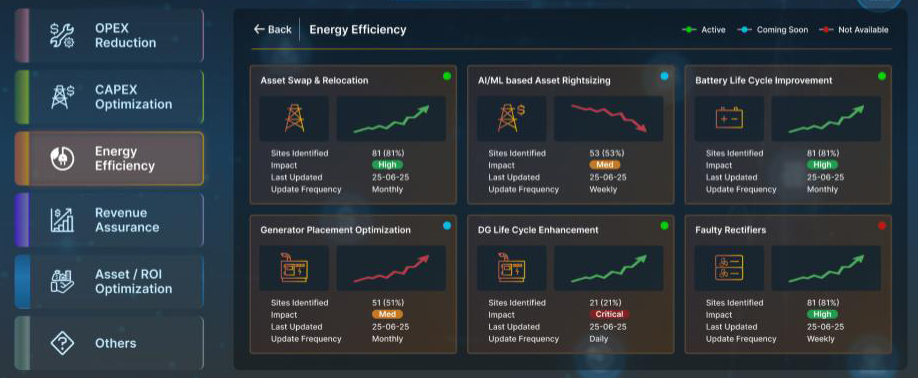

To address the needs of telecom operators, PLC Group has demonstrated its comprehensive remote monitoring and control solution which not only provides environmental temperature control, but insights, visibility, and control of all power sources on the off-grid site. Our controllers and environmental sensors integrate with all energy sources such as wind, solar, batteries and generators, allowing customers to access real-time analytics and alerts over email and SMS to take timely action.

Our system provides real-time analytics and alerts on:

- Wind and solar energy production and trends

- Site loads

- Fuel status, alarms, consumption trends

- Generator energy, run time, maintenance and fault alerts

- Overall site temperature, alarms and alerts

We installed our universal controller, TCU NG, as well as various environmental sensors and surveillance cameras, which ultimately provide Actionable Intelligence to our customers to optimize the network in a timely fashion and reduce OPEX. Our solution allows our customers to:

- Detect failure and allow users to reset it remotely that saves visits and down time

- Take manual actions in case of failure to turn on/off or reset the devices

- Reduce maintenance visits

- Reduce environmental impact due to less generator runtime

- Increase energy efficiency and reliance on renewable resources

Results:

Through our remote monitoring and control system, our customers were able to experience:

- 26% fuel savings

- 15% extra green energy produced

- 15% overall OPEX reduced

- Reduced carbon emissions and more

Let’s make this difference in your mission critical facilities. Let’s talk.

#remotemonitoring #ictcooling #rewnwableenergy #reducecarbon #telecomsites #telecomshetler #telecommonitoring #datacenter #5g #telecom